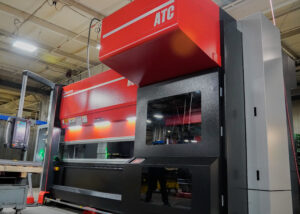

DeWys Manufacturing Invests in 2 ATC Press Brakes

DeWys Manufacturing, Marne, MI – is thrilled to announce the addition of two new Amada ATC Press Brakes to its facility. These automatic tooling change press brakes are equipped with high-precision tooling, multiple tool manipulators, and AMNC 3i Control. This machinery is welcomed to the company’s location in Marne, MI.

The incorporation of these automatic tooling change press brakes has unlocked a multitude of benefits for both the company and its customers. Shorter lead times, advanced manufacturing techniques, and the ability to handle variable lot sizes are just a few advantages that customers can now enjoy. The high-precision tooling ensures unparalleled quality in every product, while the automated tool set-ups enhance efficiency and productivity.

One of the standout features of these press brakes is the integration of AMNC 3i Control, a cutting-edge technology that guarantees consistent bend angles. Additionally, the presence of an integrated bend sensor and an energy-efficient drive system not only ensures precision but also contributes to sustainability efforts by reducing energy consumption.

This investment in state-of-the-art machinery also highlights DeWys Manufacturing’s dedication to operational excellence. By reducing energy usage and optimizing production processes, the company is not only enhancing its service to customers but also minimizing its environmental footprint. The introduction of two new Amada ATC Press Brakes at DeWys Manufacturing marks a significant milestone for the company. This strategic investment not only demonstrates DeWys’ commitment to staying at the forefront of advanced manufacturing technology but also reflects their dedication to providing exceptional metal fabrication services to their customers.

These new additions are more than just machines; they represent a leap forward, embodying DeWys’ vision for the future – a future where innovation, quality, and people reign supreme. As these press brakes begin their operation, they not only shape metal but also shape the future of manufacturing at DeWys, ensuring a legacy of excellence that will endure for years to come.