When manufacturing a metal assembly, every step matters—from fabrication and welding to finishing and final inspection. One of the most critical finishing steps is applying a protective and aesthetic coating. Powder coating is an essential part of this process, offering durability, efficiency, and cost-effectiveness for fully assembled products. At our US metal fabrication company, we integrate powder coating into our production process to ensure that metal parts and assemblies leave our facility with a durable, high-quality finish.

Here’s what else you need to know about and why it’s considered an essential step in producing a finished assembly.

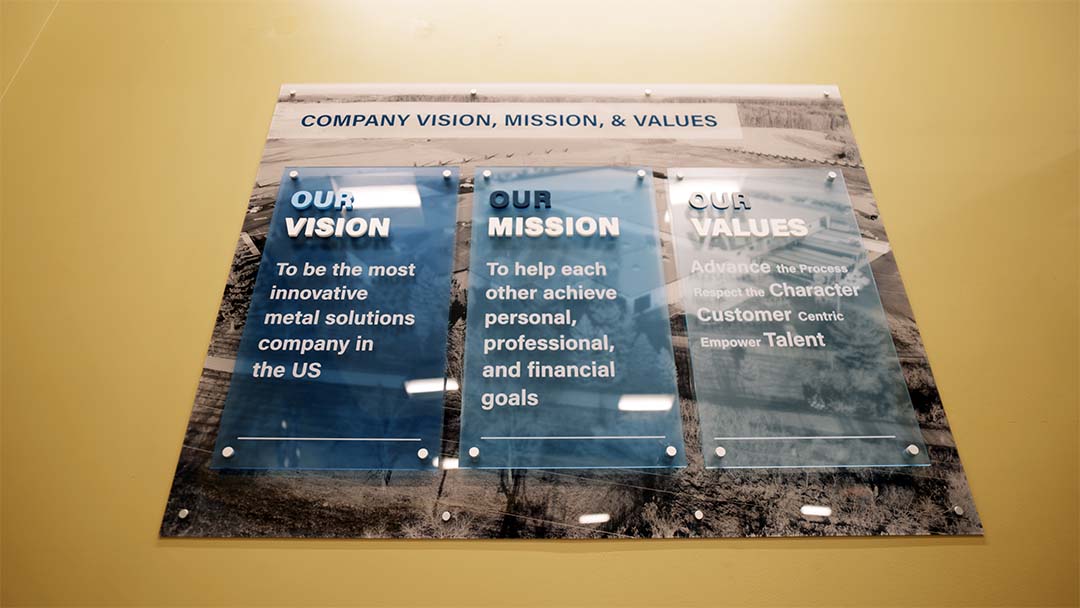

Partner with DeWys Metal Solutions

Powder coating is more than just a finishing option—it’s a crucial part of producing a completed metal assembly. With superior durability, cost efficiency, and fast turnaround times, it ensures that products leave the manufacturing floor ready for use.

At DeWys Metal Solutions, we specialize in precision metal fabrication with high-quality powder-coated finishes. Contact us today to learn how our can support your next project. Call (616) 677-5281 or fill out our online contact form.